Derived from the word ‘Beta’ and ‘Carrot’, ‘Beta Carotene’, is a plant pigment found in carrots. Beta Carotene while entering our body gets converted into Vitamin A which is an essential micronutrient. It helps one maintain good vision, lining of respiratory tract, regulation of skin cells and proteins. All carotenoids, including beta-carotene, also possess antioxidant abilities.

Many organizations produce beta carotene microspheres for medicinal purposes. The product comprises of about 50% Carotene, while the remaining portion gives the required stability and support to the sphere, thereby retaining the potency, throughout the shelf life.

Our Bangalore based client, Dynadis, had been undertaking the development of beta-carotene microspheres in their modest size equipment. However, as they endeavored to enhance their productivity, it called for setting up highest production capacity.

Getting one step closer towards the larger goal, a meaningful trial run was conducted. With this smooth preliminary testing, we not only gained client’s confidence but it also led to their decisive move of procuring our production scale equipment.

The process commenced shortly under the required guidelines and practices, viz. appropriate light, temperature and humidity level, i.e. subdued light and less the 25 deg.C & RH NMT 45%. Every effort was made to eliminate the possibility of heat generation through constant feed rate and by incorporation of addition equipment that gave provision for chilled water circulation.

The initial equipment with the client gave an output of around 97% while the equipment set out by us delivers around 99% output with bare minimum wastage. The change in output has been the result of double/twin extruder that promise enhanced productivity in a shorter time span. Critical challenges such as wear and tear arising due to material sticking in the container or screw feeders is also duly taken care off.

Below is the detailed study of the laboratory trial conducted for the client

OBJECTIVE

To prepare beta carotene microspheres from the pre mixed powder, in which Beta Carotene was dispersed in suitable diluent.

SCOPE

Beta carotene Premix powder was provided by client and Fablife to conduct trials using the premixed beta carotene powders to meet the sphere size of around 500 microns and NLT 90 % should pass through the screen size 35.

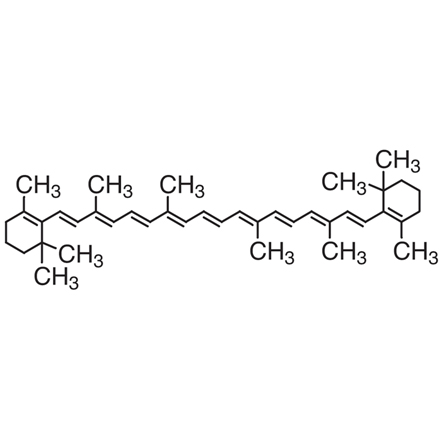

MOLECULE PROPERTIES:

| Beta carotene is considered a pro-vitamin A carotenoid, meaning that the body can convert it into vitamin A (retinol). Additionally, beta carotene has powerful antioxidant properties.

The molecular formula is C40 H56 and the molecular weight is 536.88. Sensitive to Air, Light and Heat |

|

PRECAUTIONS:

Considering degradation temperature (above 60 Deg.C) of BETA CAROTENE, precautions are taken throughout the preparation process.

EQUIPMENT USED:

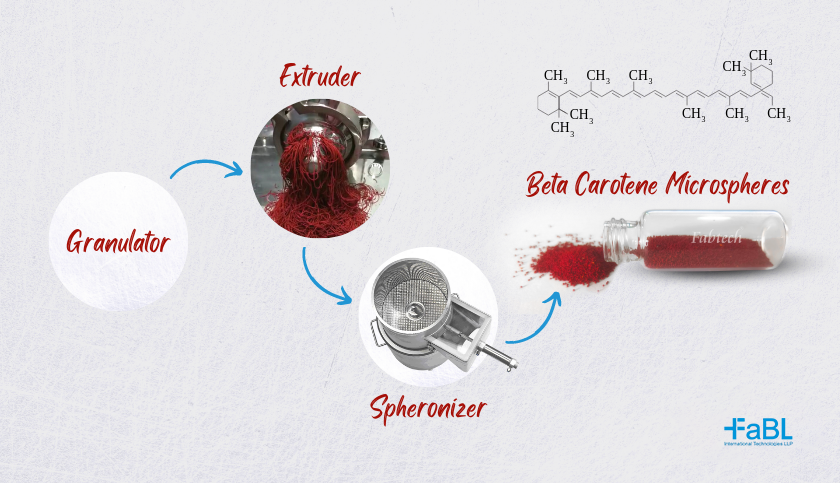

Lab model Low shear mixer/granulator, Extruder, Spheronizer, fluid bed dryer, mesh size 35

PROCESS:

The ingredients are mixed and wet mass was prepared using granulator. The prepared wet mass was passed through cone screen of 0.5 mm diameter perforation with slow feeding rate in the extruder at speed between 50 to 75 RPM. The collected extruders are charged into the Spheronizer with 3.2 mm chequer plates. The spheronization process was started at speed between 500 to 800 RPM, for 3 to 5 minutes. The formed spheres are dried using lab model fluid bed drier at bed temperature around 45 deg.C. The dried pellets are passed through 35 mesh, which is equal to 500 microns.

CONCLUSION:

- The granules prepared with the proposed process, are monitored and evaluated by client. The results of critical quality parameters are found satisfactory.

- The objective was achieved with the client required pellet size of 0.5 mm spheres.

- With the proposed equipment’s and process, there is no impact on the product quality parameters.

We effectively utilised our experience, technical skills and resources to deliver quality outcome through premium machines within the committed duration.